How To Make A Window Frame For Glass

How to make shed window frames

Making shed window frames can sometimes exist the only option. It may be that you need to replace some one-time garden shed window frames and can't discover the right size or it may exist that you are building a new shed and merely fancy building your own window frames for a challenge.

Either fashion there are quite a number of details to empathize and get right to make sure that you get the sort of operation that you lot want. So, lets accept a wait at these details first and so get into the step past step process of shed window frame structure.

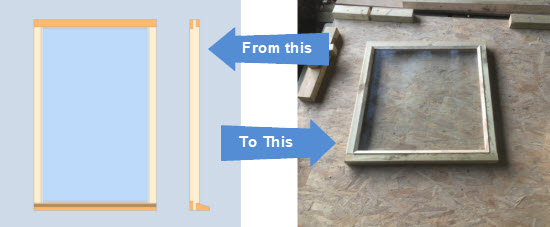

Shed window frames from concept to completion

Shed window frames from concept to completion

What are some of the details required to make shed window frames water and weatherproof

The outset thing to address is that these are shed windows, not house windows. They share many details common to all windows simply shed windows don't need to fabricated to the same cost/performance standards as house windows.

House windows are quite a technological marvel, having a host of standards and design practices to ensure that indoor living spaces are dry out, draught free and durable. A shed window doesn't demand to perform to the same level as a firm window, just they certainly do demand to do an effective job of letting light into your shed whilst keeping the h2o out.

Making your own shed windows gives you the opportunity to save coin whilst also gaining an appreciation of the details that go into window construction, too as the huge sense of satisfaction of making something that will work well for many years.

The details that we need to consider are:

- 1. What type of timber to use for the shed window frame

- 2. What size timbers to use for the window frame

- 3. What type of joint to use to connect the shed window frame members

- 4. The options for glazing your shed window

i. What type of timber to use for the shed window frames

This depends on how long you would like your shed to final. The main enemy of whatsoever shed window is the combination of h2o and sunlight. Sunlight repeated heats and cools the timber which over the huge number of cycles in a twelvemonth causes the timber to dissever. Water will find its way into whatever splits in the wood or gaps in joints and over the years will initiate decay.

So, for whatever timber you choose if y'all can provide protection to the timber with regular maintenance and application of a skillful quality paint or stain and then that will prolong its life.

Many shed windows are constructed from redwood timber and 'dip treated' against decay. Combined with regular maintenance and detailing this approach can requite many years of service. In this projection I utilise force per unit area treated (tantalised) construction timber. This isn't peculiarly fancy but gives a serviceable and durable window. If this was from a large window manufacturer then all the components would exist pressure treated/tantalised subsequently fabrication and then that all the cut sections of timber were fully protected.

This isn't the case here, then if you lot are particularly concerned and your window is particularly exposed then treating all of the cut surfaces with something such equally SikaGard Wood Preserver and painting prior to assembly will requite additional protection.

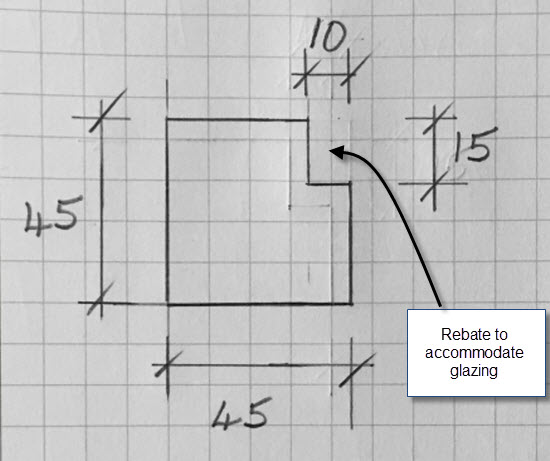

2. What size timbers to use for the shed window frame

For the shed window frames in this example I used 45x45mm (2"x2") timber for the top and sides and a section of 95x45mm (4"x2") for the window cill. These members gave a good dimensional balance to provide the forcefulness and stability for a single glazed window and also reasonable dimensions for plumbing equipment the drinking glass and securing to the crude opening in the shed wall. Each of the sides and acme member take a 10x15mm groove machined in them to accommodate the glass and glazing bead.

Typical section through timber for shed window frame

Typical section through timber for shed window frame

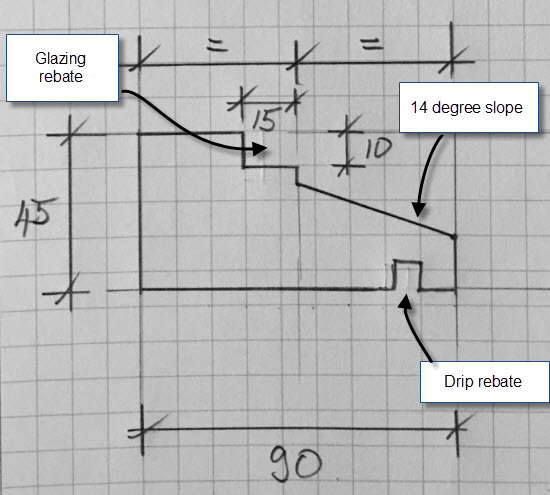

The window cill is a different section than the rest of the frame. By machining the bottom section of the window out of 4x2", the cill and the window frame are fabricated out of a single piece.

Section through shed window cill showing details

Section through shed window cill showing details

In that location are a couple of points to note here, the slope of the cill and the drip groove.

1. The window cill is cutting with a xiv degree gradient to help information technology finer shed the rain.

2. The drip groove on the underside of the shed window cill is there to force the h2o running downwardly the window and onto the cill to drop off onto the ground, rather than continuing to catamenia underneath the cill and back into the shed.

Now I have introduced you to the various parts of the shed window frame let's have a look at how to brand them, fit them together and install the shed window into the wall of your shed.

3. What type of joint to use to connect the window frame members

The options for connecting your shed window frame members range from the simple butt joint to complex routered connections which require quite complex tooling. A quick overview of iii types of shed window frame connection are:

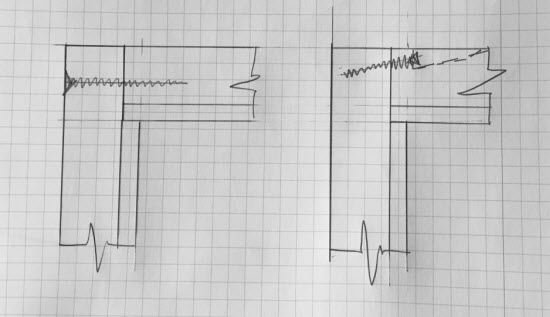

The unproblematic butt joint.

This blazon of joint is very minimalist and would be frowned upon by many. However, I take seen it used successfully on sheds that I have repaired so don't dismiss information technology out of hand immediately. The articulation requires a pocket-sized notch to be cut in the stop of the 2 horizontal timbers and the frame members are continued with screws as shown. Screwing into timber stop grain isn't the strongest way of connecting so if you wanted some boosted strength so using pocket screws would be a practiced improver.

Detail of butt joint. Left mitt side is with elementary screw to secure frame members. Right hand side is amend connection using pocket pigsty spiral.

Detail of butt joint. Left mitt side is with elementary screw to secure frame members. Right hand side is amend connection using pocket pigsty spiral.

The 'bridle' joint.

This joint is similar to a mortice and tenon joint but with ane end of the mortice open. The articulation is held in place with glue and can exist farther strengthened with a wooden dowel or star dowel.

Detail of shed window frame joint

Detail of shed window frame joint

Auto cut joint

A more than sophisticated looking joint can be accomplished by using track and stile router cutters this achieves a similar strength to the determent articulation. But of course teh ultimate window making machinery would exist to use a spindle moulder, but and then y'all are getting into the realms of house windows, which isn't what this article is about!

The butt joint and the bridle joint tin both be cut with a hand saw or saw bench. The auto cut joint is cut either on a router table or spindle moulder. So for this project I take shown the bridle articulation which is stronger than the butt joint.

4. The options for glazing your shed window

Traditionally, glass was held in in the window frame with metal glazing sprigs prior to applying putty around the perimeter of the window.

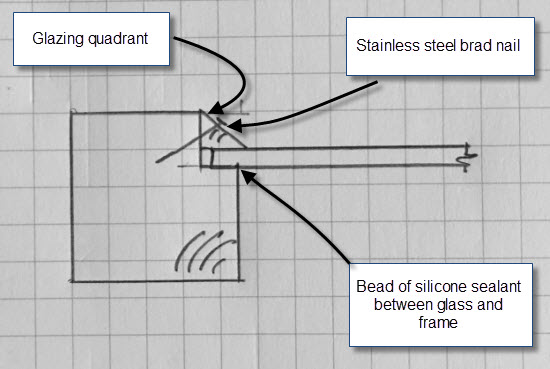

Many shed windows which are externally glazed don't use any sealant. The glass is just placed in position and a glazing quadrant held in place with 15mm long pins. If yous want a better seal, or more likely to terminate the glass rattling in the pane, then run a dewdrop of silicone sealant around the perimeter of the glazing rebate before placing the glass. The seal betwixt the glass and the frame volition make the articulation h2o proof.

Department through window showing how glass is held in place

Department through window showing how glass is held in place

Completed shed window frame

Completed shed window frame

The very simplest method of holding the glass in place is to just create a slot on the within face up of each fellow member of the frame. This allows you to insert the glass as you get together the frame. This is proficient in some ways for security equally the glass cannot be removed without dismantling the frame. Nevertheless, if the glass gets broken there is no mode of replacing the pane without removing then dismantling the shed window frame.

Most frames don't accept this slot, but use the rebate system. And the glass can be easily replaced if it becomes broken.

How to make a shed window frame step by step

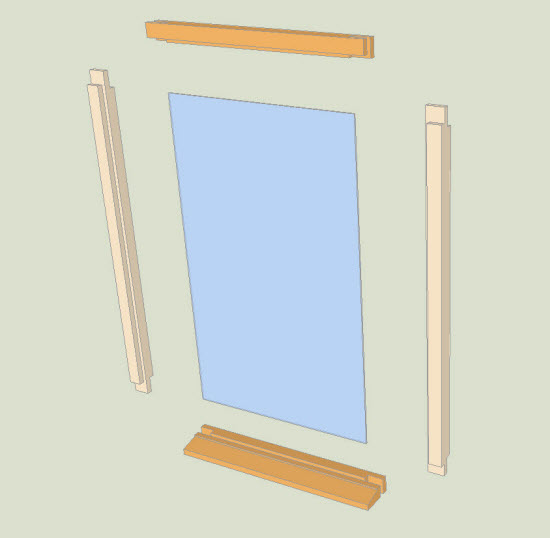

The post-obit sequence is a shed window frame that I made using the drawing beneath.

The window is a fixed, not-opening, window. It is made from pressure treated timber, three sides are 2x2" and the lesser is machined from 4x2".

Components to be fabricated for this project

Components to be fabricated for this project

The members are joined using a bridle joint at the corners and glued together. The frame is then screwed into position to connect it to the shed frame.

The window is glazed with 4mm toughened glass fitting into a 10x15mm rebate around the frame. The glass is sealed around the perimeter using a bead of silicone sealant and then fixed in place with 10x12 timber glazing quadrant fixed with stainless steel brad nails.

And then now that you know almost the project let's get started:

The first stride is to cut the members to length.

To summate the length, allow 2.5mm tolerance all round the frame.

For this frame with a standard 610x610mm pane of horticultural glass the frame members were xxx+ii.5+610+2.5+xxx = 665mm long.

Equally the window frame is to be square then each member is the aforementioned length.

Members cut to length and with joints formed on the ends

Members cut to length and with joints formed on the ends

A rebate is cut in each fellow member of size 10x15mm to accommodate the drinking glass and the glazing quadrant. This can be cut using a router in a router table or using a table saw.

The window cill department is cut using the bract of tabular array saw set up to a 14 caste bending. The drip groove is cutting to 10mm deep and with 3 passes of the saw to grade a groove 7.5mm wide.

Now that yous have the basic shed window frame stock, the next step is to cut the joints.

Cutting the joints

No special equipment is required to cut the joints. It is perfectly possible to cut these simple joints with a paw saw and to employ a hammer and chisel to remove the waste material where necessary. For this projection I used a table saw and some jigs to speed upwards the cutting process.

As with any woodworking projection of this type take great care to mark out the joints and understand which section of wood is to be removed before taking it out. Act in hast apologize at leisure!

Once yous take all the joints cutting, check that they fit

Dry fitting the frame

Attempt fitting the four members together to check that they fit. Measure across the diagonals of the frame to make sure that the frame is square (both diagonal measurements the same). Also check that the drinking glass fits in the glazing rebate.

Gluing the parts together

When you have ensured that all the parts fit together well it is time to make the joints permanent. Before you start to glue make sure you have some clamps to concur the pieces in place earlier the gum sets. I used some fairly standard bar clamps, only you could apply some straps to apply some pressure if y'all don't accept these to paw.

I used some water proof polyurethane gum for the joints. Too as being waterproof this expands into the joints and fills any small gaps.

Window frame 'dry-assembled' with pane in place to bank check the fit

Window frame 'dry-assembled' with pane in place to bank check the fit

Glazing the window

The drinking glass is best fitted after the frame is installed into the shed. This is because if you are a chip rough with the installation it is quite easily possible to deform the frame and fissure the drinking glass.

A bead of silicone sealant is applied around the edge of the rebate and the drinking glass is then laid on to this. Some other bead is then applied to the perimeter of the drinking glass and the 10x10mm glazing quadrant stock-still in place with stainless steel pins.

I cutting my own glazing quadrant from a hardwood such as oak or sugariness anecdote, which is resistant to decay.

Completed window with glazing quadrant in place

Completed window with glazing quadrant in place

Close up detail of glazing quadrant

Close up detail of glazing quadrant

Conclusion

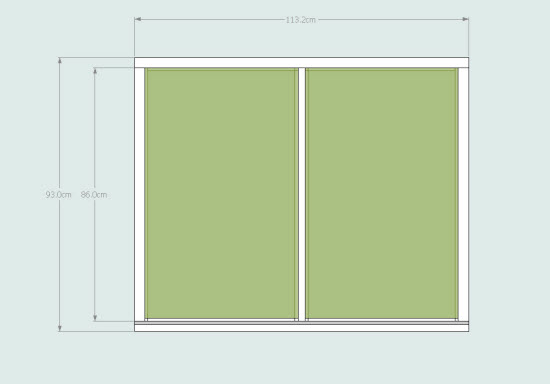

Of course, yous don't have to be limited to a unmarried paned window.

Window frame with two panes

Window frame with two panes

I hope you institute this article useful for making stock-still shed window frames.

If you would like more information let me knowand I can expand it to include opening, side or top hung shed window frames besides.

More information on the best type of shed window glazing tin be found here.

Custom Search

Proceed in affect with our monthly newsletter

Shed Building Monthly

Source: https://www.secrets-of-shed-building.com/shed-window-frames.html

Posted by: henrythadermly.blogspot.com

0 Response to "How To Make A Window Frame For Glass"

Post a Comment